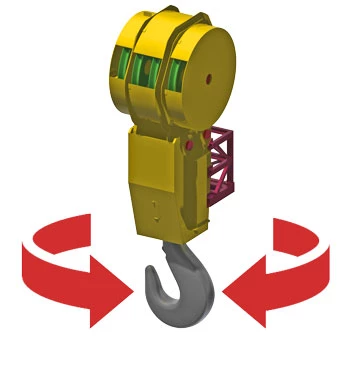

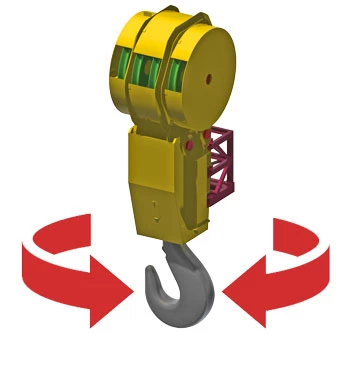

They are special bottom blocks enabling the rotation of a suspended load around a vertical axis by means of motor drive, usually controlled from the crane operator cabin or by means of remote control without intervention of service on the ground.

The drive can be solved as electromechanical, hydraulic or pneumatic and enables unlimited rotation of the hook in both directions. Starting and stopping is controlled so, in order there should not occur the overrun of suspended load, thereby the consequent vibrations. The bottom block can also be equipped with a system for load positioning, which will assure that after issue of command to rotating the bottom block hook will automatically stop in determined position.

Popisek

PopisekIn case if bottom block with motor hook rotating is to be installed instead of the existing bottom block on already operated crane, then this bottom block is structurally designed so, in order the existing bottom block could be directly replaced without requirement of any mechanical modifications of the existing trolley structure. It is only necessary to provide a cable lead of power supply and control signals to the bottom block.

The bottom blocks can also be fitted with weighing system of various design and weighing accuracy. The detected load mass can be shown on display directly on bottom block, transferred on crane eventually even out of it, or there can be used combination of these methods.

In case if electromagnet or hydraulic grab are suspended on bottom block, then this block is fitted with socket for power supply and control of these devices. The supply voltage and control signals are led to the bottom block from the trolley by cable.